"Concordia" Chef's Knife

"Concordia" Fine Custom Chef's Knife

- Size (Knife): Length overall: 14.0" (35.6 cm), Blade Length (at cutting edge): 9.0" (22.9 cm), Thickness: .141" (3.6 mm)

- Size (Stand with knife): 12.75" (32.4 cm) tall, 4.75" (12.1 cm) wide,

13" (33.0 cm) long

- Weight: Knife: 15 oz. (425 grams) Stand: 7 lb. (3.2

kilograms)

- Blade: 440C high chromium martensitic stainless

tool steel, proprietary T3 deep cryogenic treatment, hardened and tempered to Rockwell C58, mirror polished

- Fittings/Bolsters: 304 austenitic stainless steel, mirror polished

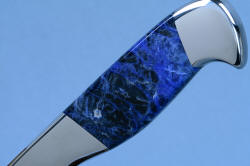

- Handle: Polished Sodalite Gemstone (Brazil)

- Stand: American Black Walnut, American Poplar,

inlays of Sodalite gemstone, Black Galaxy Granite (India), base of

Black Galaxy Granite, neoprene feet, engraved black lacquered brass,

stainless steel fasteners

- Knife: This is a custom Concordia, one of

my most popular chef's knives, custom made for a great client. The

knife is a classic design, technically a "Sabatier" style,

originating in France and well-recognized all over the world. The

Concordia is large, and I've made this one with the finest treatment

and presentation possible for a singular knife and a beautiful, bold

stand.

- Blade: The Concordia's blade is 440C high chromium

martensitic stainless steel,

my most requested steel for many reasons. It's highly

corrosion-resistant, extremely tough, and has very high wear

resistance, while capable of an extremely thin, sharp, and

long-lived cutting edge. This is not only due to the steel alloy

content, it's because of my specialized proprietary heat

treatment. This steel is treated with my T3 deep cryogenic process, one that is

extremely lengthy and complicated and takes a full week, with

33 specific steps and temperatures ranging from over 1800°F

to -320°F! This process is so dynamic and transformative

that it creates extremely fine grain, low asperity, maximum

development of martensite, and a tremendous amount and

distribution of complex carbides. The performance of this blade

is exemplary, a blade that will literally last for generations

with minimal sharpening, high toughness, and high overall

strength. I will flatly claim that the condition of this blade

is superior to all others made; no one has or employs this level

of treatment detail in any knife, anywhere! In this Concordia, because my client

requested a very stiff overall blade geometry, I've created a thick,

wide spine and an extremely thin cutting edge. This is

accomplished with a 12" hollow grind (accomplished with a 12"

diameter profile). The blade is smooth and clean, with a fully

tapered tang for balance. The curvature of the blade is just

right for mincing, chopping and board work, and qualifies as a

master chef's main blade design. The heel is deep, dropping an inch

below the forefinger groove, and 1.9" below the spine. The blade

is hygienic and smooth and beautifully mirror-polished for easy

cleaning and high food safety.

- Fittings: I bolstered the Concordia with

zero-care high nickel, high chromium austenitic stainless steel.

This is the same steel used in stainless nuts, bolts, and

fasteners, and with 18 percent chromium and 8 percent nickel,

it's incredibly tough. This is a zero-care stainless steel, it

will not corrode, no matter what it could encounter in any

kitchen. The bolsters are rounded, contoured, and polished for a

comfortable grip, and the front bolster is elongated along the

spine of the knife. This is done for several reasons. One is to

give a wide, flat area for the thumb to rest in heavy cutting

chores, rather than bearing down on a narrow spine. The other

reason is to allow a "pinch" type grip along the spine for finer

dicing and board-work. The bolsters are dovetailed to anchor,

support, and bed the knife scales permanently to the handle.

- Handle: The handle scales chosen for

this project were at the request of my client, who wanted a

bold, blue color. Choosing Brazilian Sodalite also added

some fascinating pattern and light play in the striking

gemstone handle. Sodalite is a feldspathoid, often used in

jewelry, and this particular gemstone has a black matrix for

a bold, rich contrast. The scales are bedded to the tang

with a stress-free mounting, locked under the bolster

dovetails, rounded and smoothly polished. The fit is

flawless.

- The knife feels sizeable and

capable in the hand,

with the balance point exactly at the heel of the blade. When

gripped with an overhand spine pinch, this large knife feels light

and maneuverable, smooth and fresh, ready for any chef's task. A

simple rinse is all it usually takes to clean the bright, polished surface

in most functions, and the knife satisfies

food safety

requirements. While the spine is thick and strong, the

wide and deep hollow grind lightens the weight considerably.

The point is extremely thin and aggressive, yet tough and

well-supported by the blade geometry. This is a master

chef's knife made for accurate cutting, slicing, mincing,

and dicing, for generations. A true family heirloom.

- Stand: As with all of my knives, a commensurate

and beautiful stand was necessary. This is a stand designed not only

to grace the kitchen environment, it's an extremely stable base for

the knife that will safely store and display the knife for

generations. I made the body of the stand in American Black Walnut,

our nation's most valuable domestic hardwood for a reason. Walnut is

smooth, uniform, and durable, while being naturally beautiful. The knife blade edge rests on a thin slice of Poplar, a

soft and lighter-colored hardwood just right to bed the edge of the

knife and give a contrasting line in the form. I designed and created

the

sculptural form I named "splash" for the

stand, which works well with the deep, watery-blue of the

Sodalite gemstone knife handle. The design has water-splash shapes,

also recognized as paisley-figures, a very ancient form that is

attributed to dolphins, water, and fish. This form is represented in

the open carving and four inlays in the walnut. The inlays are

precise, deep, substantial, and clean, in polished Sodalite gemstone from Brazil, which display the rich royal blue

color. The black plagioclase feldspars in the Sodalite exhibit a

fantastic light play of iridescence called labradoresence. The other

inlays are of polished Black Galaxy Granite from India, the same

material as used in the base.

The inlays are bold, curved and domed forms that stand above the

surface of the walnut to give a distinctive view from any angle,

while being inviting to the touch. This compliment of materials and

placement brings together the blue and black in the handle,

the inlay gemstone, and

the massive black granite base. Because one of the main components

of this form is the cutout shape, it displays a bit of the knife

blade, while offering a handle to move the weighty stand around in

the kitchen environment. For safety, when the knife is in the stand, no part of

the cutting edge is accessible to the fingers. I wanted to make this piece as stable as

possible, so I cut and finished a thick, heavy slab of the black

granite (over 1" thick). This ornamental and functional stone is dense, hard, and

solid, with bronze-gold colored flecks of Enstatine (Bronzite)

throughout. The granite is mined from Chimmakurthi in Ongole district in the State of Andhra Pradesh in India,

and is so durable that it's used for countertops and architectural

components.

The walnut stand is secured to the granite base with stainless steel

screws, and the base has inlaid feet of neoprene to protect any

surface the stand rests on. The neoprene also aids in creating a

non-slip grip. Into the bottom (see photo below), I've inlaid a

legend plate in engraved black lacquered brass for provenance. I'm

very proud of this stand; I've saved the design for use in future

projects. The wood is oil-sealed and a periodic waxing of wood and

stone is all that will be needed to maintain the piece. In the

photos below, you can see that the stand itself is an independent

work of sculpture, and one of the features I'm known for. After all,

a plain knife block is so... pedestrian! This stand begs for the

chef to grip the bold handle.

- This is a wonderful project, and I'm thankful to my client and

patron for his patience, support, and input. The piece will last for

generations of use and eternal beauty. I've taken a ridiculous

amount of photos below; please look them over to appreciate this

work the way I have enjoyed making it!

Thanks A. K.!

Jay,

That is so unbelievably beautiful, I am at a loss for words. The downside of museum quality

is that it belongs in a museum for everyone to see and I will no doubt feel a little guilty using

this to chop produce. But I will not deny this work of art its purpose, so I shall definitely

put it to work.

—Later—

Jay,

Looks like a dream, cuts like one too. Has transformed the tedium of a marathon of holiday cooking to a joy!

--A.

Please click on thumbnail photos